Caliper Duplication & Twisted Object – Tyler

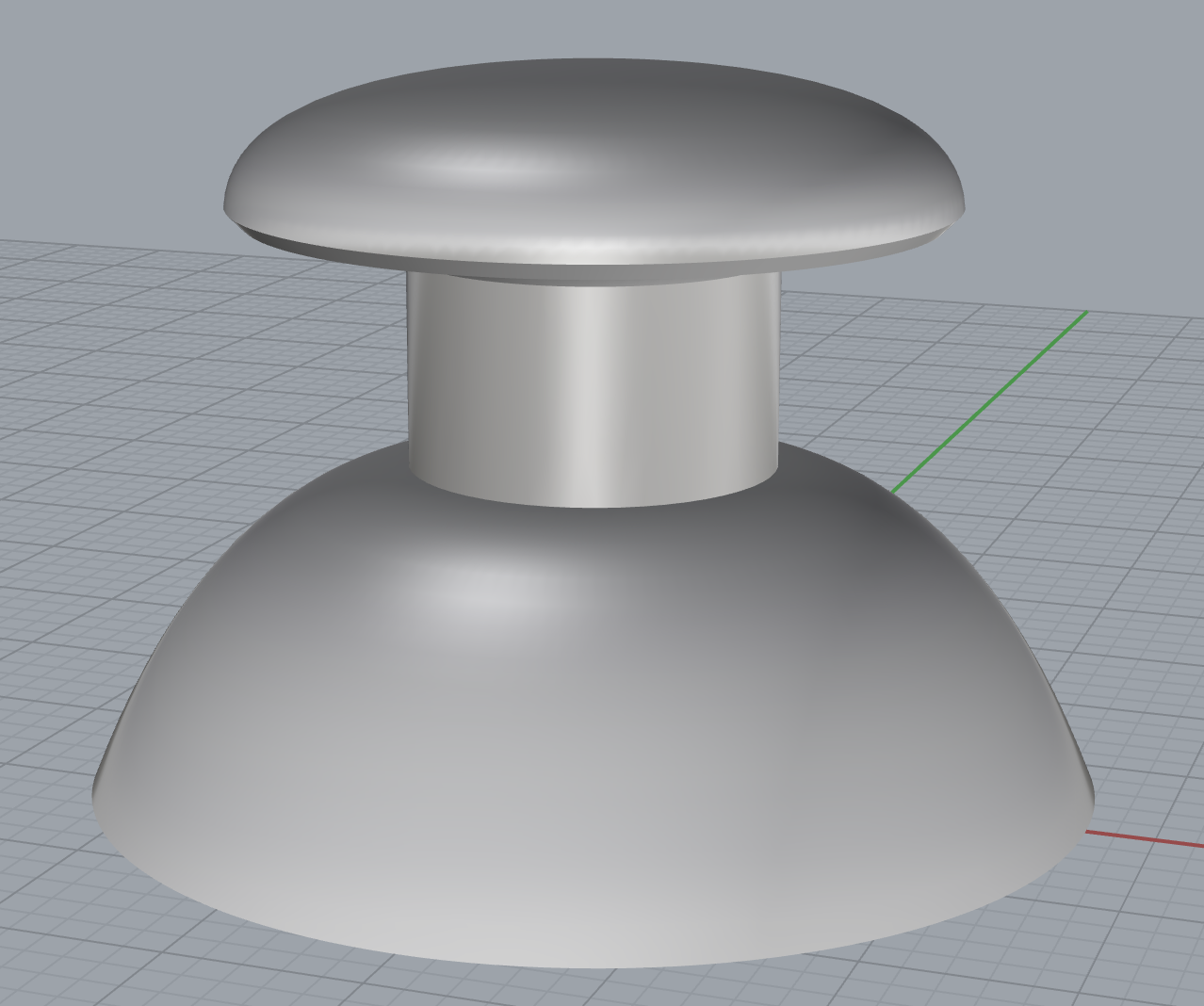

For the object I duplicated using calipers I chose a thumbstick/joystick, since I’ve been working with them in designing arcade interfaces. To model this in Rhino, I translated the important measured points from one half of the outline onto the X,Y axes. I placed the points by manually entering their positions on the command line, and then drew lines to connect them.

After that, I joined the line and revolved it 360 degrees to create the solid.

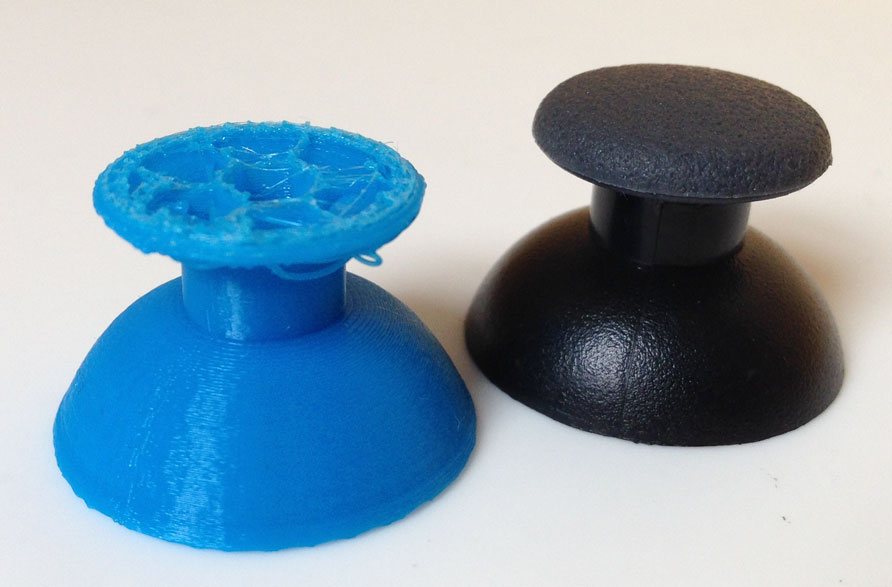

Unfortunately at the end of printing, the filament got twisted on the spool and stopped feeding into the nozzle, which is why it’s missing the top few layers. I had thought there would be more issues with the overhang, but these weren’t very bad.

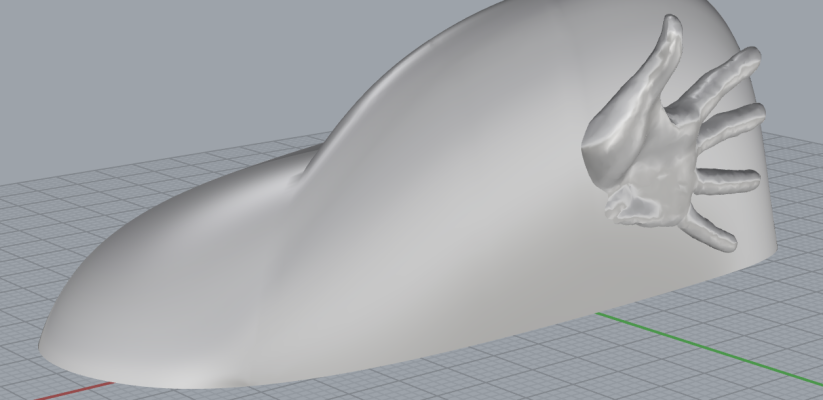

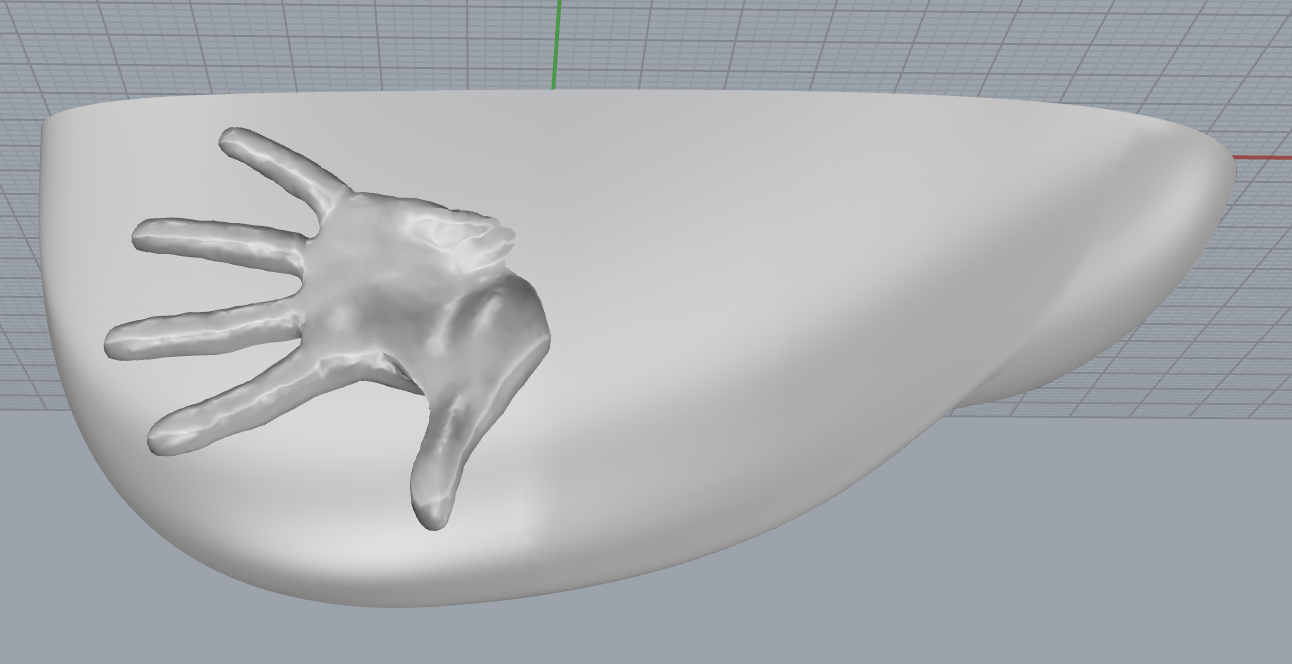

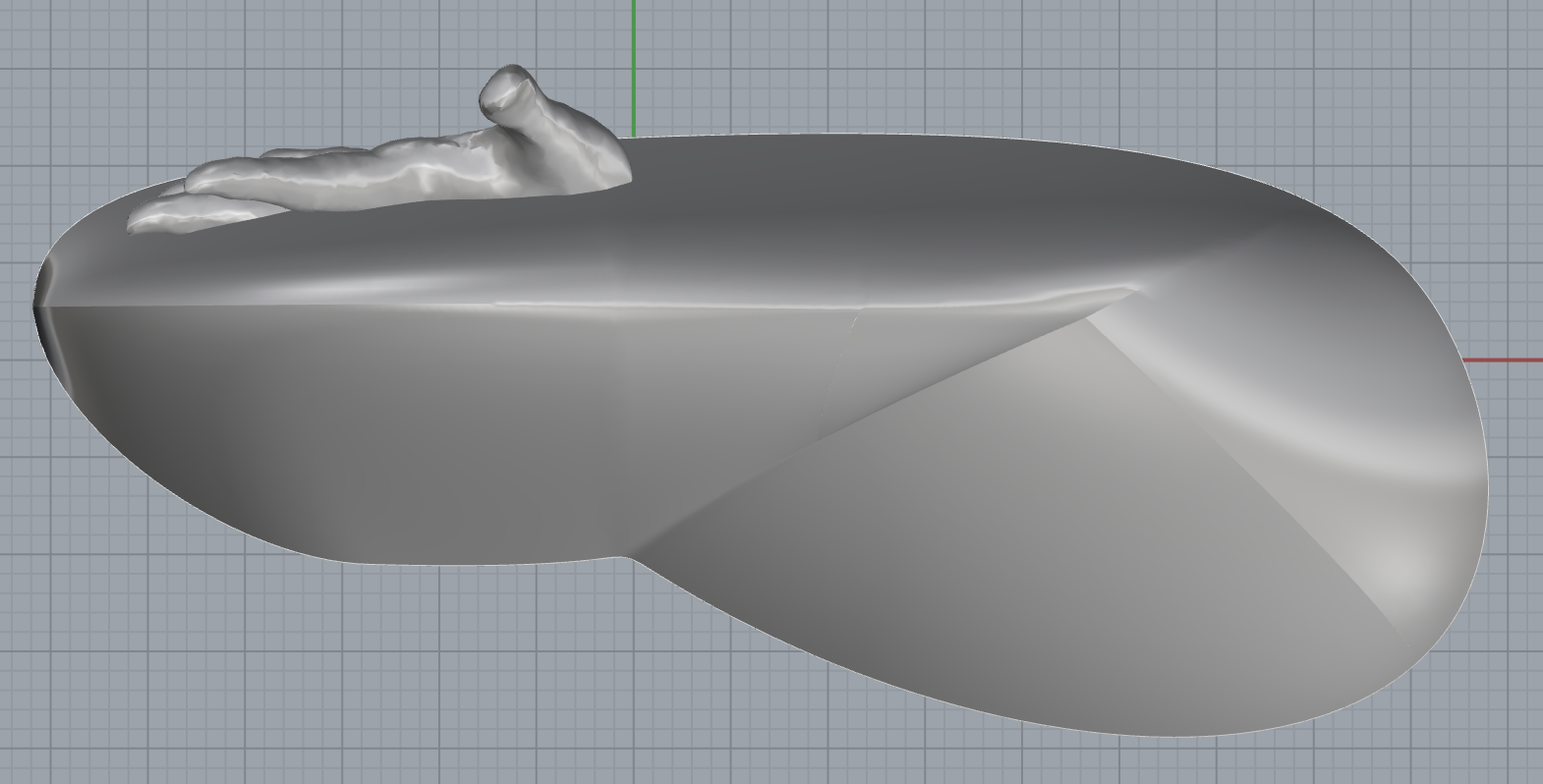

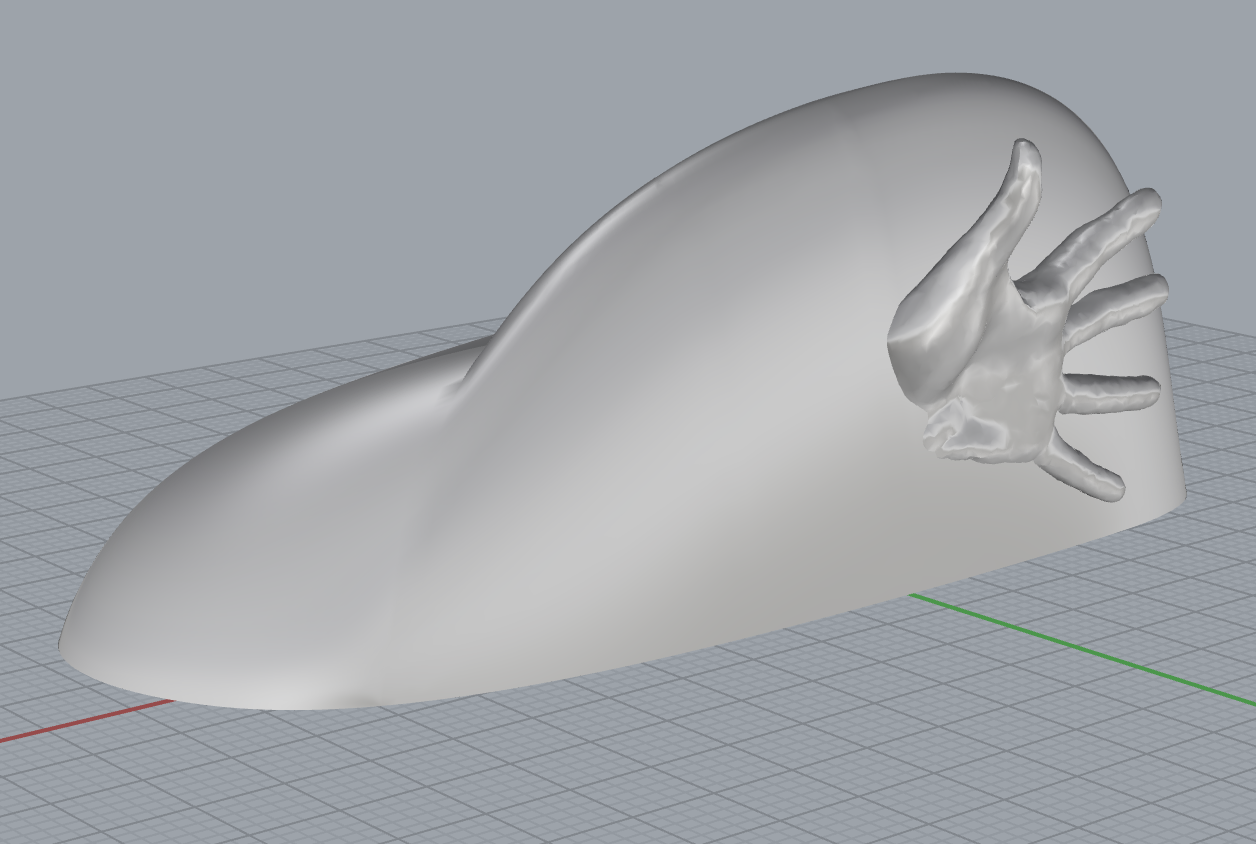

For the twisted object, I wanted to replace a toilet flush handle with something unexpected. I decided to add a human hand to the handle so you could low five your toilet as you flush.

I first took the handle off my toilet and measured it with calipers.

I spent hours in Rhino trying to figure out how to form this shape. It wasn’t easy as it’s so organic, and I wanted it to be as close as possible. I started by outlining the size of the handle and main measurements with rectangles and points. Then I created base of the shape as a few curves, which I joined together. Then I created a number of vertical curves that spanned the width of the base curve. Eventually I had the shape together.

I had a lot of trouble figuring out how to make the shape into a solid though. Eventually I landed on the Polysurface from Network of Curves tool. But as I tried this tool I realized I needed to cut up the curves into smaller sections and create numerous polysurfaces one at a time.

I had the shape of the toilet handle, and then looked on Thingiverse for a hand form to use with it, since I wanted to use something natural. I found one and imported it as a mesh and integrated it with the handle. I split the mesh using the polysurface to remove the parts that weren’t showing. I tried to join the mesh with the polysurface but couldn’t figure out how to get that to work. I also tried turning the polysurface into a mesh and using Booleans to join them, but that also wasn’t working.

Unfortunately, when I got to the 3D printing lab I found that there was an issue with the model and it wouldn’t load correctly in the MakerBot software, so I couldn’t print it. I tried to check for naked edges and found a few, but couldn’t figure out how to solve them with the complexity of the shape.

So I decided to print the joystick model instead.